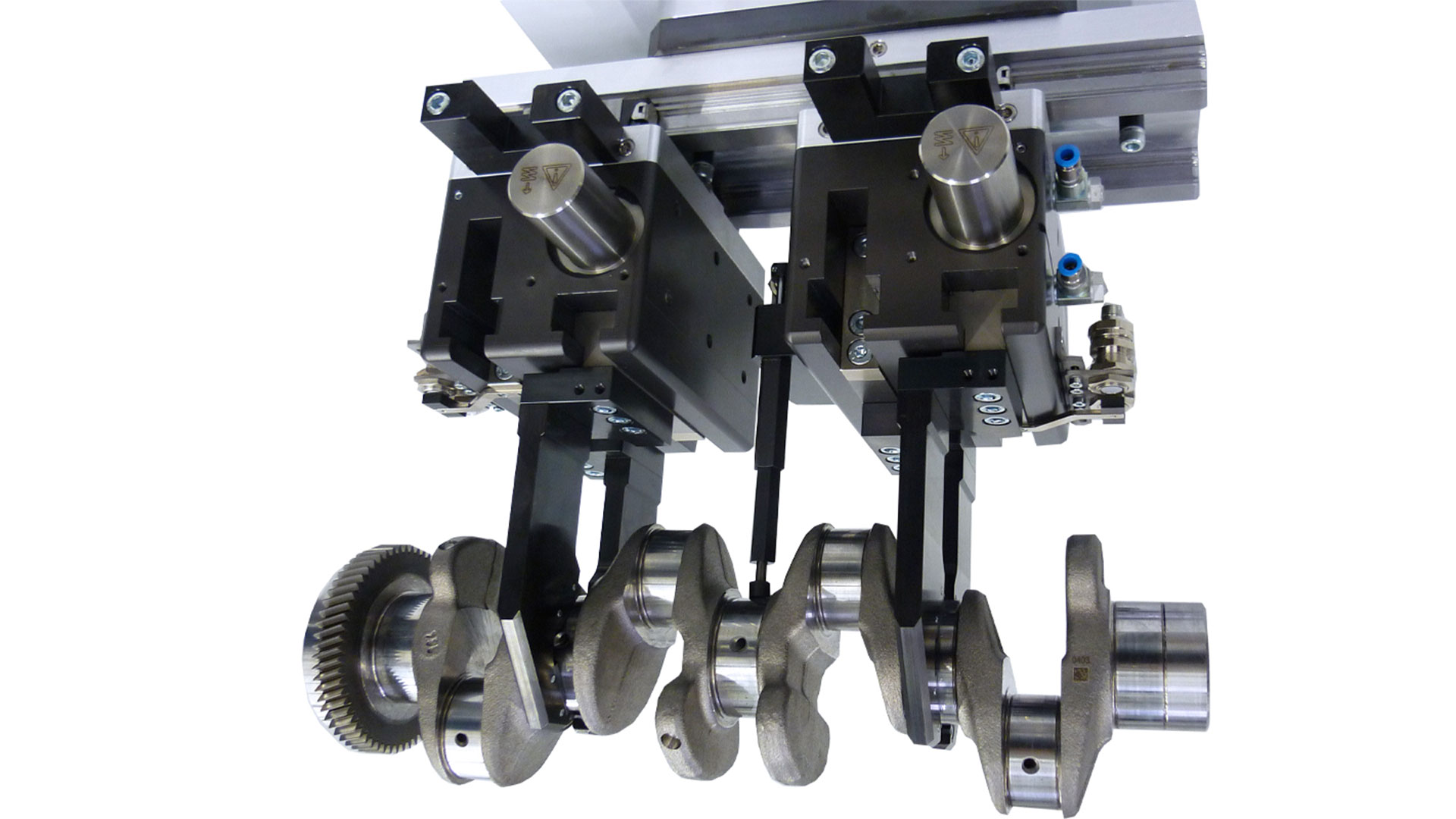

Gripper for crankshafts

System solutions | Mobility | Automobile | Drive train for combustion engines

For loading and unloading a crankshaft production line, a flexible, efficiently optimized handling system needed to be developed that is capable of handling current and future 3-, 4- and 6-cylinder crankshafts of varying designs. Adjusting the different bearing clearances and thus the grip points, automatically and without additional drive technology was a special challenge here.

As the solution, two Zimmer Group standard grippers (GH6400 series) are fastened on a linear guide. An in-house clamp ensures the correct position when clamped. If a new shaft type is run, the grippers are locked in place at a fixed point, the clamp is released and the gantry adjusts the grippers to a new pitch.

IP40

IP40 Pneumatic

Pneumatic External gripping

External gripping

| Drive type | PNEU |

| Max. gripping force | 1840 [N] |

| Gripping concept | FORM |

| Gripping safety device | FED |

| Max. stroke | 80 [mm] |

| IP class | IP40 |

| System weight | 55 [kg] |

| Max. workpiece weight | 25 [kg] |

| Max. workpiece temperature | 80 [°C] |